Historically, “good” design for HVAC systems has swung like a pendulum between two outcomes: energy efficiency and indoor air quality.

Devastating wars of the mid-19th century saw the realization that disease spreads faster in crowded hospitals with poor ventilation. In the 1880s, Massachusetts became the first state to write minimum ventilation requirements into law.

100 years later, the oil embargo of the 1970s saw designers strive for energy efficiency by reducing ventilation rates. However, this trend was short-lived—in the 1980s, the pendulum swung back toward ventilation when Sick Building Syndrome became a recognized health issue.

The Leadership in Energy and Environmental Design (LEED) rating system, launched in 1998, tries to strike a balance. Through its various versions, LEED awards credits for both energy savings and increased ventilation. Despite this, LEED’s “synergies” section notes that the two credits are often at odds.

The COVID-19 pandemic threw this conflict into focus. By early 2020, attention had moved to designing buildings for a new Net Zero Energy (NZE) future by maximizing energy efficiency, only for a pandemic to bring indoor air quality back to the forefront.

With this double demand for energy efficiency and indoor air quality, developers, landlords, office managers, and even school superintendents are increasingly asking: How can we achieve both?

The answer lies in good HVAC design.

Results were especially strong in situations involving crisis response, information usage, and strategy. This shows how Demand Control Ventilation (DCV) technology is worth implementing in all kinds of environments, whether in an office building, a school, or a laboratory. After all, it is in everyone’s interests for a building’s occupants to function at their highest cognitive level.

Tip 1 — Optimize Ventilation with Demand Control Technology

Building owners and developers must meet minimum ventilation rates, which are defined by state codes. Most are based on some version of ASHRAE 62.1, which defines different ventilation rates depending on a space’s area, population, and usage. These factors account for the difference in ventilation needs of, say, a person working out in a gym (20 cubic feet per minute, or CFM) and a person working in an office (5 CFM).

While meeting the minimum is a good place to start, we can do a lot more.

One solution is Demand Control Ventilation.

DCV senses the amount of CO2 in an indoor space and increases or decreases the amount of fresh air coming in to keep CO2 levels low. DCV offers all the cognitive and health benefits of increased fresh air. It also saves energy by reducing levels when less fresh air is needed.

Buildings can better self-regulate if their HVAC systems are designed to be able to operate above the code minimum, even if only occasionally. This approach keeps air quality as high as possible without over-ventilating when spaces are unoccupied or have low usage.

Tip 2—Improve Thermal Comfort with a Building Management System (BMS)

A BMS helps to save energy by controlling temperatures based on whether the building is occupied or not. In “unoccupied mode” temperatures are allowed to vary, which prevents any unnecessary energy use. But when the building becomes occupied again, it will quickly come back to the desired temperature.

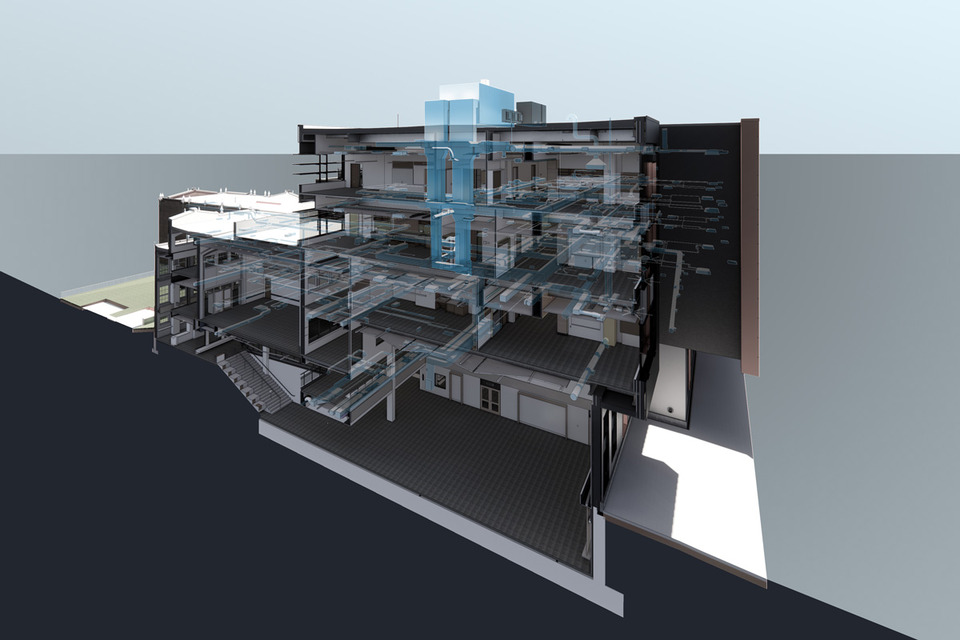

321 Harrison Ave

View Project

SMMA successfully modeled a BMS at 321 Harrison Ave (above), a lab/office building in Boston. By using setbacks of 80°F in cooling and 63°F in heating, our energy models showed a 5.5% reduction in energy use while keeping unmet load hours to less than 100. In short, we were able to save energy without any reduction in comfort or indoor air quality.

Somerville High School

View Project

Tip 3—Improve Thermal Comfort With Ceiling Fans

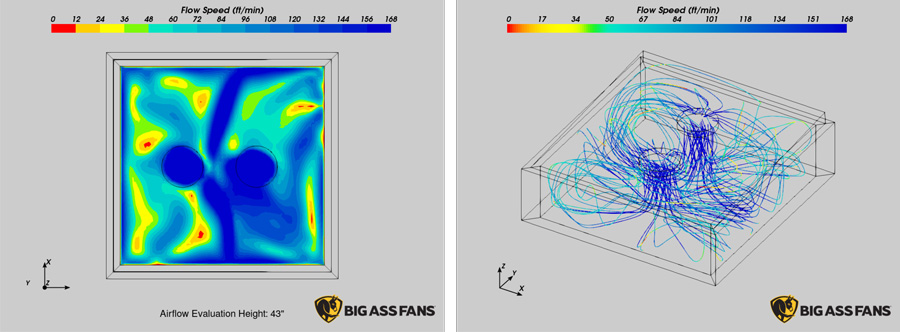

Ceiling fans can also improve comfort while saving on energy. At Somerville High School, our engineers used ceiling fans in the classrooms to achieve a 5.2°F cooling effect. This means the school can set their thermostat almost 4°F higher while still having the same comfort—a substantial energy saving.

Big Ass Fans Haiku ceiling fans improve thermal comfort while saving on energy. The model above shows this in a classroom, but the same principles apply to commercial and residential spaces as well.

Tip 4—Optimize Humidity with Energy Recovery Wheels

In New England summers, “it’s not the heat, it’s the humidity” is a common saying. But for occupant health in winter, a bigger deal might be: “It’s not the cold, it’s the lack of humidity.” A Mayo Clinic study found that students in classrooms with no humidification had 2.3 times more absences caused by influenza-like illnesses than students in humidified classrooms.

Humidification is expensive and can use up a lot of energy.

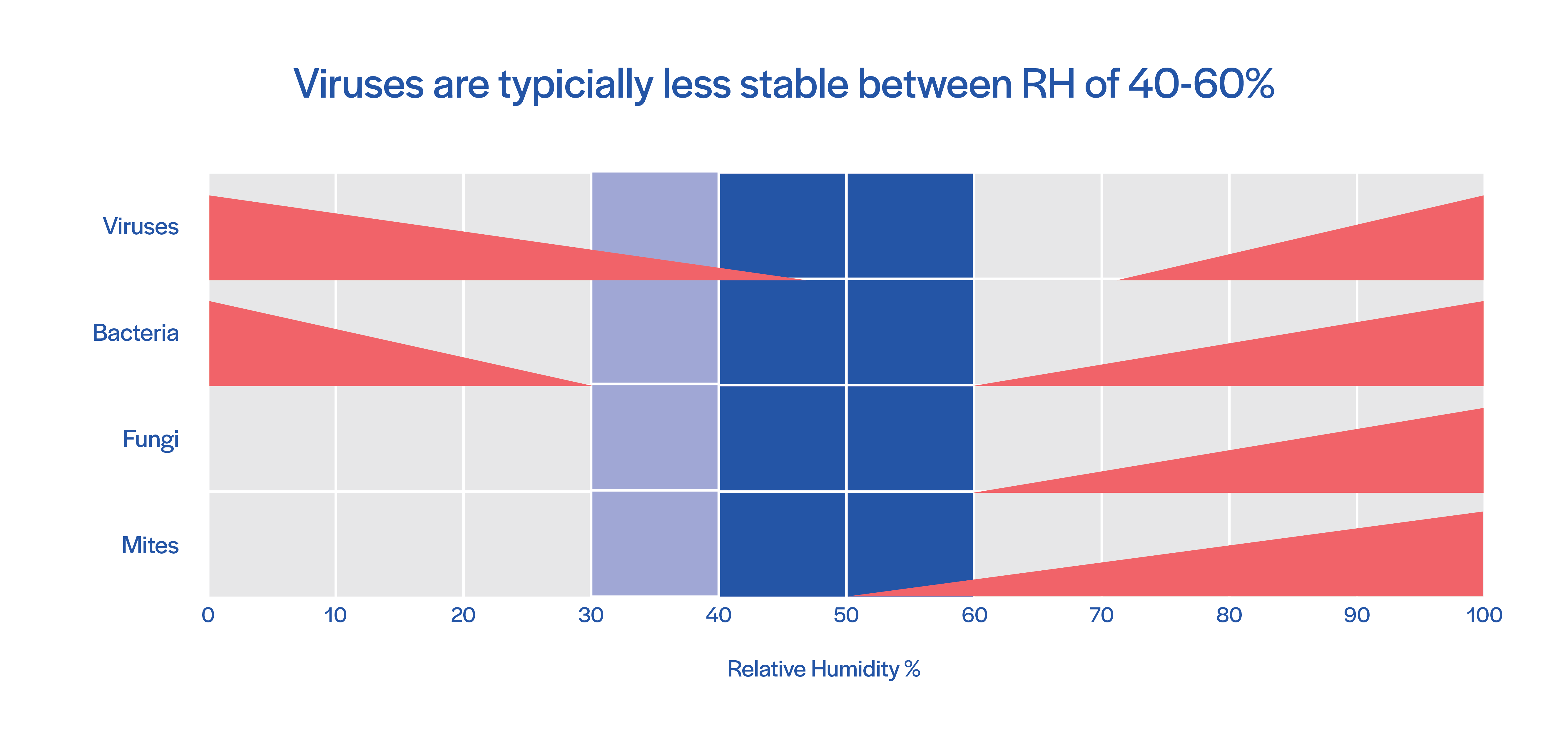

However, keeping relative humidity between 40-60% has been shown to correlate highly with positive health outcomes. By contrast, humidity outside this range causes negative outcomes from viruses, bacteria, fungi, and mites. This is illustrated in the following chart by Trane, which uses data from ASHRAE:

Energy recovery wheels with both sensible (temperature) and latent (moisture) heat are an effective way to optimize relative humidity in buildings. This technology recovers heat both from the temperature and humidity in the air.

At Cytiva’s Headquarters in Marlborough, MA, SMMA used energy wheels in some units and mechanical humidification in others to keep spaces in the 30-60% humidity range year-round. This is bound to improve the wellbeing of the building’s occupants and give them the best environment in which to pursue their scientific work.

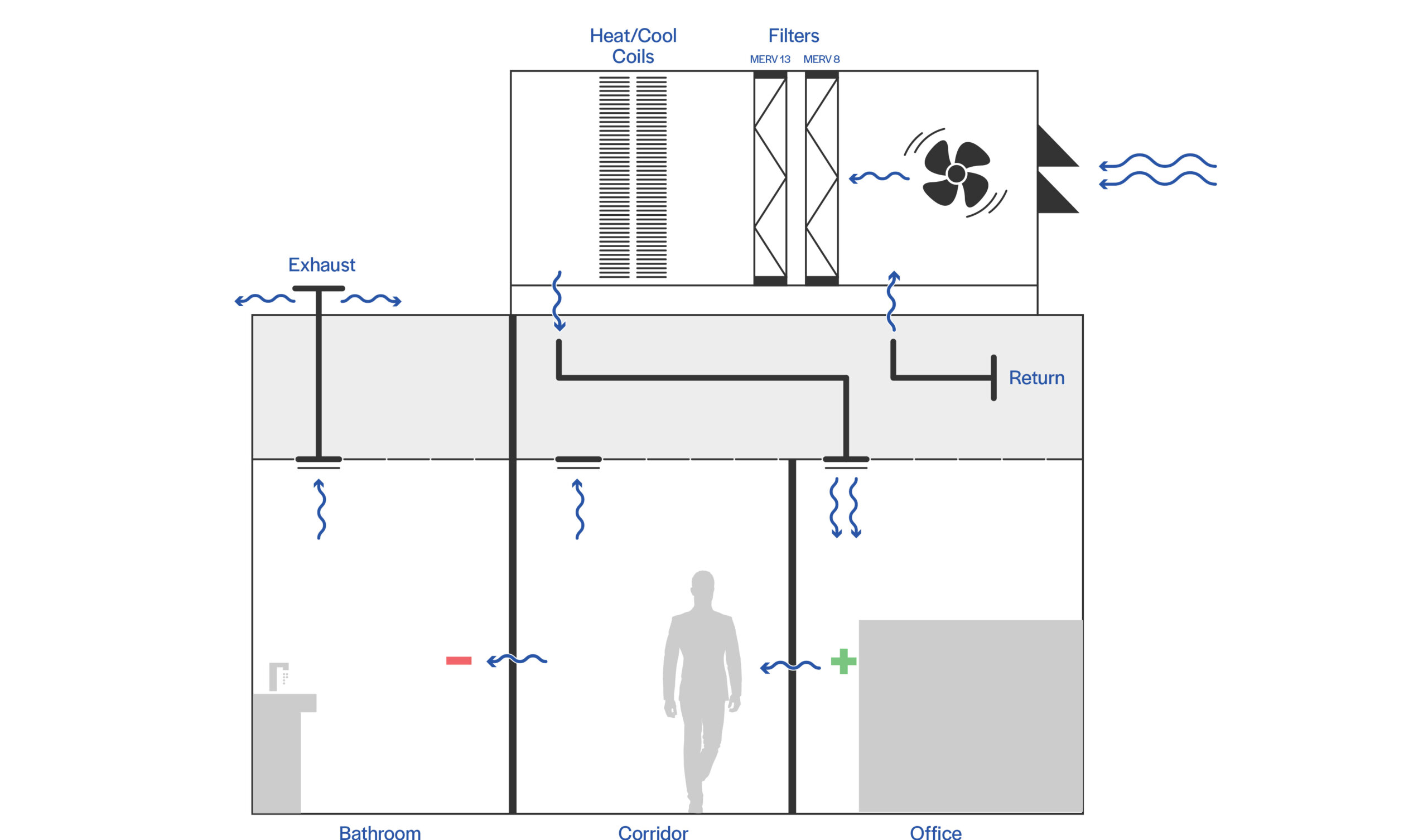

Tip 5—Treat Air Using MERV Filters, UVGI Light, or Bipolar Ionization

As well as treating air temperature and humidity, a good HVAC system will treat the particulate and droplets in the air—vital in a pandemic, but always a healthier situation for occupants.

Filtration is the first step.

MERV 8-10 prefilters and MERV 13 final filters used in air handling units will improve the air that comes into the building and remove 95% of all particulates. This long-recommended approach also helps to remove allergens including dust, pollen, dander, and fumes.

For a recent school design, SMMA equipped the DOAS units supplying ventilation to all the spaces in the building with bipolar ionization units. These units clean the cooling coils, preventing buildup of potentially harmful pathogens and sending ions out from the unit. This saves energy by preventing pressure drop caused by a dirty coil while keeping heat transfer from the coils as was originally designed. SMMA also designed the occupied spaces with MERV 13 filters on the recirculated air, further improving the environment for the occupants.

MERV 13 Filters

|Research on COVID-19 has shown that MERV 13 filters can make inside spaces almost as safe as outside spaces. MERV 13 filters are only 1% less effective than supplying 100% fresh air into a building, and use significantly less energy due to their lower heating and cooling demands.

Another effective way to kill pathogens in the return air stream is to use ultraviolet germicidal irradiation (UVGI) light. Integrating UVGI technology into a design reduces the chance of reintroducing pathogens and spreading them to other areas of the building. Similarly, needlepoint bipolar ionization has been shown to work both at point of use and by bringing ions into the space for improved air quality.

Another effective way to kill pathogens in the return air stream is to use ultraviolet germicidal irradiation (UVGI) light. Integrating UVGI technology into a design reduces the chance of reintroducing pathogens and spreading them to other areas of the building. Similarly, needlepoint bipolar ionization has been shown to work both at point of use and by bringing ions into the space for improved air quality.

Tip 6—Take Lessons from Lab and Hospital “Pressurization”

Pressurization and air flow direction control is often used in laboratories, hospitals, and even data centers. Office spaces can also benefit from the general principles of pressurization to minimize cross-contamination among occupants. By positively pressurizing private areas (where occupants spend more time) and negatively pressurizing break rooms and bathrooms, HVAC systems can provide more fresh air to occupants while removing air that has been exposed to more people.

For SmartLabs at 40 Guest Street, SMMA designed a pressurization system where all spaces either push or pull contaminants in the direction best suited to the health and safety of occupants as they conduct experiments.