The Center links LCCC with the thriving microsystems industry in Ohio.

The facility not only trains students in MEMS technology, but also serves as a valuable resource to small start-ups and medium-sized MEMS manufacturers. It is a multi-user, shared-resource center for microsystems packaging, reliability testing, and inspection.

The Center’s customers can access a range of technological services.

The laboratory suite is dedicated to quickly producing and testing MEMS, other semiconductor devices, and commercial sensors. Project management services are available to tap into the deep experience of the Center’s experts. Facility access is available for customers with trained staff who need access to state-of-the-art equipment, providing a leg-up for companies that cannot afford expensive, specialized tools. This access benefits the local economy by helping small technology companies grow.

Designing the Center was a truly collaborative effort.

The process involved client education, industry trend benchmarking, and establishing protocols for lab safety and clean room gown usage and maintenance.

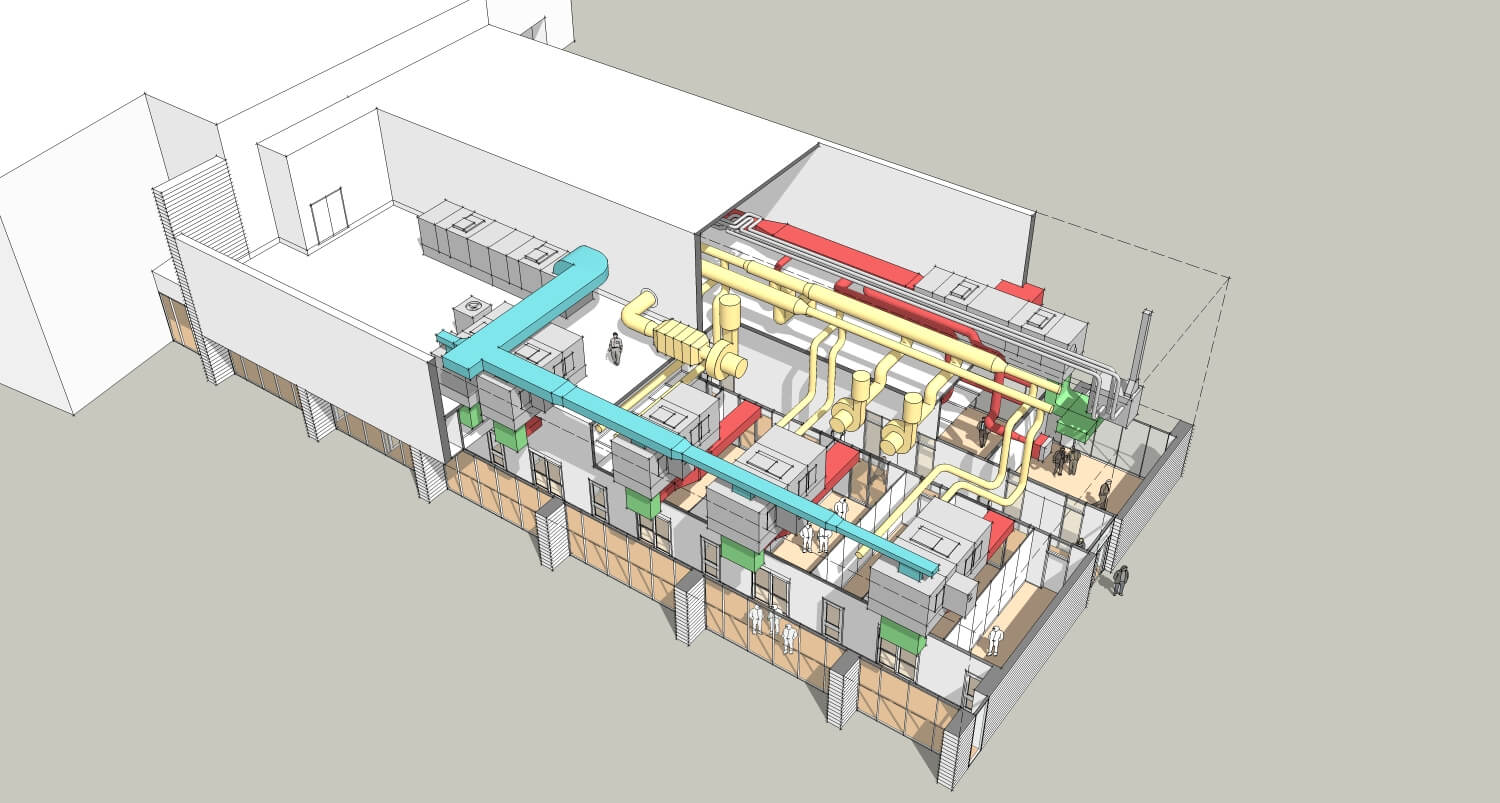

In the fast-changing microsystems world, designs must be fully changeable and scalable, able to adapt to new technologies as they hit the market. SMMA’s designs comprised Class 100, Class 1,000, and Class 10,000 cleanrooms, general lab spaces, and customer incubation areas totaling 8,800 square feet.

A combination of public and private partnerships brought the Center to life.

In addition to financial support from Richard Desich, a native of Lorain County and member of LCCC’s District Board of Trustees for 34 years, the College received a $5.5 million grant from Cleveland State University’s Wright Center for Sensor Systems Engineering. Additional support came from federal, state, and philanthropic grants and gifts, including funding from the Small Business Administration.