The single-story building has an open-plan layout divided into four distinct areas: rectification, packaging and bottling, warehousing, and office space with a quality control lab and tasting room.

Integrating new equipment while adhering to strict flammable liquid storage regulations posed a logistical challenge.

The solution involved constructing the rectification room concurrently with 9,000-gallon stainless-steel storage tanks. Meticulous planning ensured efficient installation of ventilation, fire protection, and other systems. The tanks were then carefully maneuvered into place, carried in sideways through an oversized door and tipped into place.

Previously, M.S. Walker relied on manual, labor-intensive processes.

Moving liquids between tanks required manual hose connections. Flavor adjustments involved climbing tanks and manually adding ingredients. Recipes were kept handwritten and relied heavily on memory.

The new facility boasts fully automated systems.

A computerized flow control panel simplifies liquid transfer. Dedicated stations with precise meters handle flavoring additions.

These advancements empower M.S. Walker's staff to work more safely and efficiently.

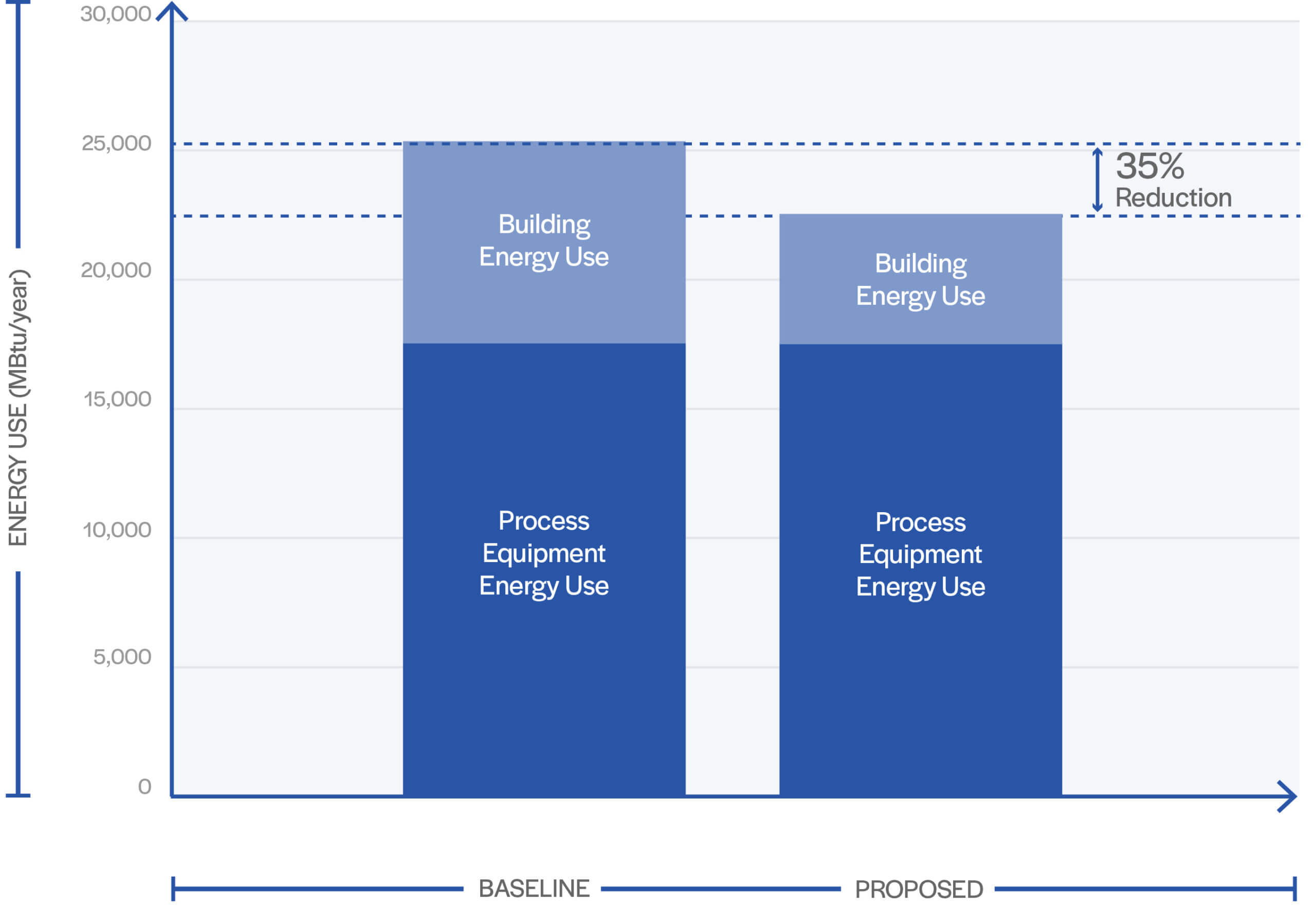

Meeting Massachusetts’ Stretch Energy Code—which requires a 20% energy reduction compared to a standard code—was a challenge. M.S. Walker’s process equipment used a much higher energy share (65%) compared to a typical office or warehouse building (20-30%). The design surpasses the Code with a 35% overall energy reduction and provides M.S. Walker with tools to better understand the potential impact of electrical demand on their facility operations.

“Thank you SMMA for the outstanding support, diligent commitment, and high level of detail. SMMA was thoughtful and respectful to our entire organization’s needs, and clearly understood our complex and varied operational requirements.”

Scott Allen, General Manager, M.S. Walker