The new facility features specialized areas for employees and customers.

The space features an open layout along with private offices, workstations, phone booths, meeting rooms, and a large training area. Visitors can explore a customer experience area near the front entrance. This includes conference rooms, a hands-on R&D lab, and prototype displays.

The design promotes a healthier, well-rounded experience for both shop-floor workers and office workers. Wellness features include an outdoor seating area, large café, and employee activity center.

A tool hall showcases Harvey’s exceptional products that solve challenging machining requirements.

The design blends office and manufacturing space with the visual journey of an accessible tour aisle. With its large glass windows, the aisle provides clear views between the offices and tool hall. Natural light and outdoor views foster a connection to nature.

SMMA’s engineers designed a series of complex systems and equipment to optimize the facility’s manufacturing process.

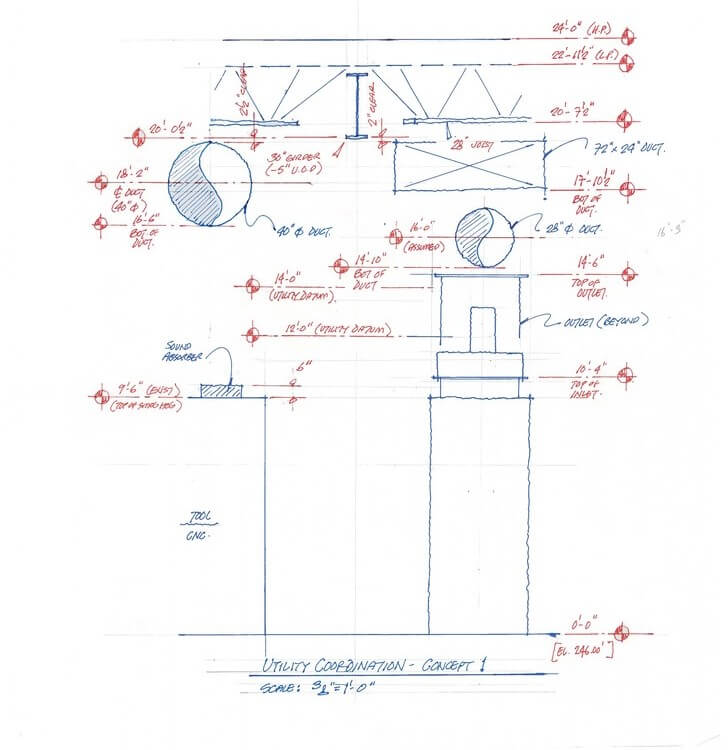

Utility Coordination

|The design team established horizontal, layered pathways below the building for the utilities based on size, weight, and requirements.

The largest pieces of equipment, including HVAC cooling and exhaust ducts, are located both vertically and horizontally to bring a certain cadence to the space.

Engineers on the project fondly refer to these pathways as a "club sandwich", with the building structure and floor serving as the "bread" and the many layers in between creating the "meat".

Suspension System

Another unique feature of the tool hall is the Unistrut suspension system. The system is hung from the steel structure every few feet, organizing major systems like the main power feed, compressed air lines, and the cable tray. To ensure these systems don’t affect the employee experience, the floor plan includes ample space, airflow, and lighting to give workers room to run the utilities and eliminate shadows from the ductwork.

Oil Supply and Cooling

A deeper story unfolds five feet underground, spanning about 150 feet across the tool hall. Each piece of machinery—serving different steel-cutting functions like grinding, polishing, honing, and coating—is fed with oil from a large trench. This oil lubricates the steel the machines cut, creating Harvey’s product.

The trench also houses two, eight-foot gravity drains and two pairs of oil supply and return lines for equipment cooling. The temperature-controlled oil matches the space and blank temperature, preventing thermal expansion. An addressable leak detection system enables workers to quickly locate leaks.

The exterior nods to the building’s dual uses.

Two distinct shapes and varying roof elevations break down the building’s massing: the higher volume for manufacturing, and the lower for office.