The new design boasts several sustainability feats.

58%

Virtual Server Increase

271

WATTS

Saved Per Server

73%

Power Reduction Per TB

1.2

MEGAWATTS

Saved Power Demand

The design team helped Dell Technologies to minimize up-front costs and support future growth.

To achieve this, the new center’s electrical systems allow additional unit substations with large transformers to be inserted as needed through back-of-house electrical rooms, leaving intact the electrical infrastructure in the labs and data centers.

The design reduces the downtime required for additional power increases. It also eliminates disturbances to the built environment, preventing revenue loss. Efficiency is further improved by reducing the number of electrical transformations. The unit substations stepped down the medium voltage from the utility directly to the voltage needed at the rack level.

Using an existing building avoids the carbon implications of a greenfield project and minimizes environmental impacts.

The design team converted existing loading dock door openings into louvers to serve the air-intake plenums. Structural elements remain, including the roof, steel framing, curtain wall, and slab. The project preserves all existing green space and locates all site utilities within the former delivery bays.

The data center currently meets a stringent Power Usage Effectiveness (PUE) objective of 1.3. This means a net decrease of 1,175 kW of connected load.

Energy-efficient cooling measures include cold aisle containment, high-efficiency humidification in the form of a non-fossil-fuel-based high pressure reverse-osmosis system, and air-intake plenums at the perimeter of the building. The latter provides the building with free cooling for over 5,500 hours each year.

Air temperatures delivered to the server inlets increased up to 75 degrees, a jump from the 58 degrees at the former center. This contributes to the total hours of free cooling and reducing the need for mechanical cooling.

One inch of rain on the center’s roof results in 280,000 gallons for potential water reuse.

Project phases I and II developed a rainwater collection system to support domestic water fixtures. As such, the project achieves a 40% reduction in potable water usage. Low-flow water closets, waterless urinals, and no permanent irrigation system helps conserve a further 38% of water.

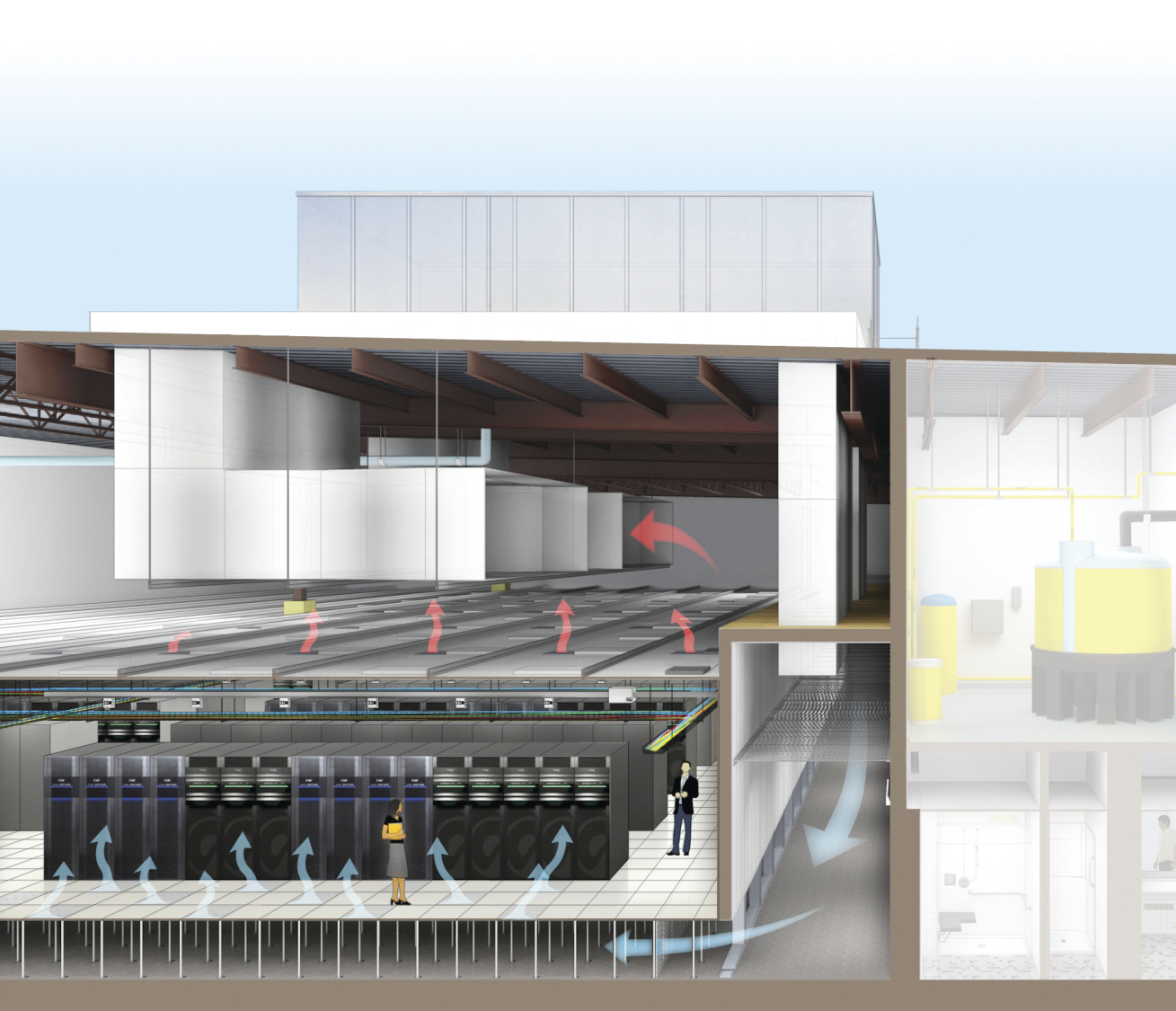

To create an efficient airflow system, the team took a holistic, mechanical design approach.

The design emphasizes air movement throughout the building. Large vertical and horizontal plenums extend the mechanical system to provide unobstructed airflow paths.

Other efficiencies include high-performance floor supply grilles, perforated plates for uniform airflow distribution, and minimized differential pressure between the under-floor and data center. Meanwhile, the air-handling units use a multiple fan-array approach to reduce connected motor horsepower.

The data center allows for equipment migration and new technologies on an as-needed basis.

- Space to accommodate future electrical substations and mechanical chiller modules to meet increased power and cooling demands

- Chilled water piping to provide supplemental cooling solutions for potential “hot spots”

- A dedicated substation built onsite with 100-megawatt capacity

- A continuous strut assembly to allow buss duct and cable tray installation, and to support a future hot-aisle containment solution

Dell Technologies can now leverage their IT resources to deliver in days what previously took months.

97%

Growth in IT demand

46%

Drop in Power Consumption

67%

Sustained New Server Demand by Virtualization

271

Reduced Watts-Per-Server

Phases I and II were completed under budget and ahead of schedule.

Dell Technologies saved $104.5 million through capital expenditure avoidance, lowered energy costs, and increased space efficiencies. Energy use was reduced by 34% and the carbon footprint was shrunk by nearly 100 million pounds of CO2. The project realized $660,000 in energy rebates from the local utility company due to its energy-efficient design. Phase III is in progress as a study and conceptual design aimed to further increase rack power densities for next-generation server equipment loads.

“The new Center of Excellence gives us a solid foundation for the future and accelerates Dell Technologies own journey to the cloud. It gives us the flexibility to offer IT as a Service to Dell Technologies business units in a cost-effective way, and puts us in prime position to share what truly are best practices with our customers.”

Jon Pierce, Dell Technologies Vice President of Global IT Private Cloud Infrastructure and Services