The light industrial category is wide-ranging: distribution centers, industrial plants, data centers, and manufacturers of everything from widgets to pharmaceuticals to semiconductors. This broadness is exemplified in the work that SMMA has done over the years leading back to our founding in 1955. Our portfolio includes manufacturers of products ranging from machinery and robotics to wines and spirits.

Every new client brings valuable experience and insight into the keys to effective design for light industrial facilities. The fact is, these modern facilities require more than just four walls, a roof, and the necessary machinery to facilitate production. Companies must also realize that effective manufacturing spaces are complex, well-designed, and responsible.

Harvey Performance Company

View Project

All light industrial facilities must meet the needs of their production operation, that is a given. But what separates a great light industrial facility from one that simply does its job? Throughout my career, I have learned that the most significant difference maker in these projects is the client’s attention to design. The level of attention paid to design elements, large and small, impacts everything from facility performance and preparation for the future, to attracting new business.

50 Otis Street

View Project

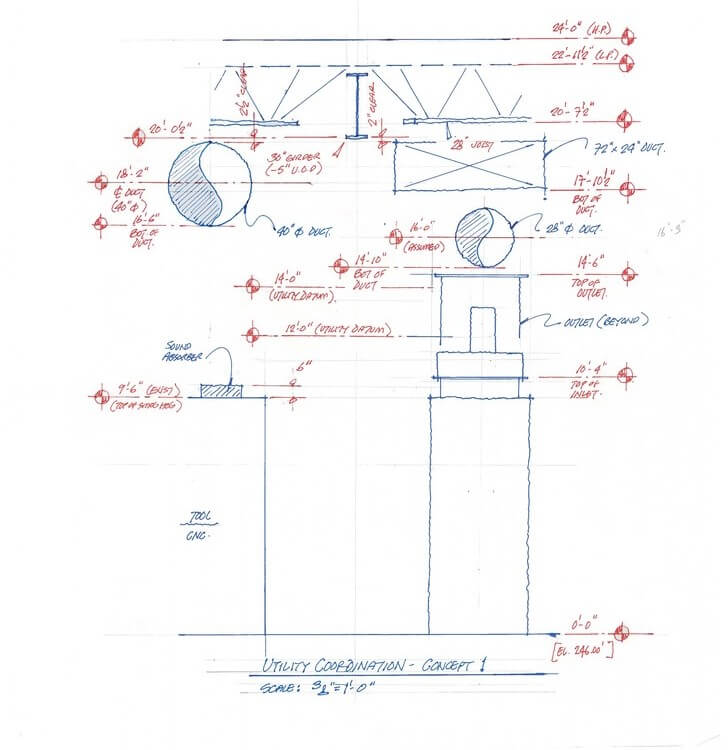

Good design can be seen in the details: Are utilities provided throughout the facility in a way that is organized, clean, and makes sense, or were the lights, ducts, piping, and sprinklers all installed individually in an unorganized way that casts shadows throughout the manufacturing floor and results in an unsightly jumble of tubes and chords? A great project occurs when a high level of attention is paid to these details, and all parties collaborate on the layout. An example of this type of coordination can be found in the "club sandwich" method utilized in the Harvey Performance Company’s facility, where ductwork and utilities like power and cooling lines are organized in neat horizontal layers creating distinctive pathways to provide for better utility coordination and easier access for maintenance, and eliminate shadows to provide a more positive impact on the human experience.

Attention to design details also applies to planning for the flow of the space. The obvious implications are in the movement of people, raw materials, and finished product. We need to be able to move efficiently around the manufacturing floor and from the storage space to the office or other amenity spaces. Just as important is the movement of machinery. If there is an array of tools, eventually one will need to be repaired or replaced, so the space must easily and efficiently facilitate that shift or removal.

Harvey Performance Company

View Project

While traditionally, manufacturing facilities are designed to prioritize production over exterior aesthetics, there is no reason why these buildings cannot be more than a plain gray warehouse when viewed from the outside. Even simple designs, bursts of color and texture, or distinctive entryway elements can transform a structure from bland and boxy to visually interesting, connecting the structure with its tenant’s brand without sacrificing production capabilities. Providing a functional and well-designed facility in a way that is appealing to the eye will help the tenant boost productivity and engagement and make a good first impression on both employees and guests. Good design also enhances a company’s ability to attract and retain the best in employees, engineers, and operators who want to work in a thoughtful, collaborative, and efficient environment.

The design of a manufacturing facility should not be solely focused on production when the space also can work as a business development tool. A well-designed facility puts the building to work for the marketing department by presenting the company brand right at the front door and showcasing the manufacturing process in an organized, sophisticated way for potential customers to see the company’s work first-hand.

M.S. Walker Fine Wines and Spirits

View Project

Well-designed light industrial facilities are built to last. Redundancy in the facility’s systems should be considered at the outset to provide at least N+1 redundancy, meaning that the facility has a reserve utility or piece of equipment that can be turned on to account for system failure or maintenance. More sensitive systems or processes that cannot be allowed to shut down must be given higher levels of redundancy, sometimes providing a completely independent, mirrored system ready in case the first system goes down (commonly referred to as 2N redundancy).

Many of these facilities are designed with planned growth in mind. We purposefully organize utilities in a way that lends itself to expanding into a new addition based on the company’s business model or plans to step up manufacturing. It is one thing to design a manufacturing system for the near (predictable) future, but what about in twenty years? Fifty?

We need these facilities to be flexible for the unknown. Companies could be making something completely different in the future than they do today. Often, the best way to plan for this uncertainty is to add additional floor space or height to the building’s shell. If unsure about what tomorrow will bring, I often advise clients to think about everything getting bigger and requiring more utilities. Adding extra space and height allows for potentially larger, utility-demanding machinery to live in the same building that houses the machinery for what is being used today.

With growing concern about climate change, increasingly prominent energy regulations, and a desire for corporate social responsibility among major organizations, planning for sustainability is another important step when thinking about the future. Implementing strategies to lower energy usage that exceed local energy codes, installing more efficient fixtures, modern insulation technologies, and rooftops fitted for potential PV arrays should all be considered in planning for an energy-efficient light industrial facility.